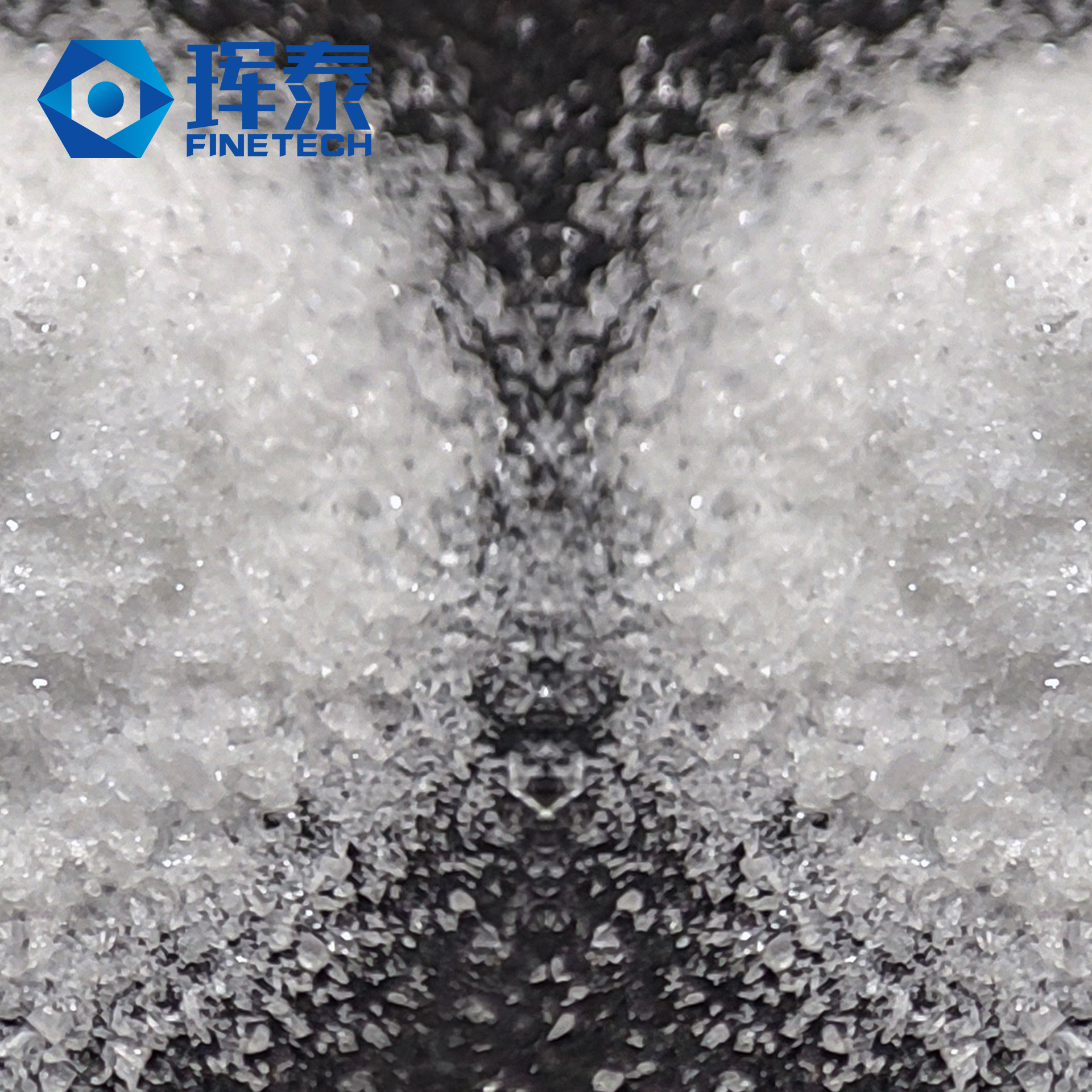

Fused mullite is a refractory material that combines high quality and multiple functions. With its excellent performance and wide range of application fields, it has won the favor of numerous customers. As a professional refractory material supplier, we have conducted in - depth research and development and continuously optimized the production process of fused mullite to ensure that each batch of products has stable quality and superior performance.

Fused mullite stands out in the refractory material market due to its seven unique advantages:

1. Extremely low coefficient of thermal expansion: It can effectively resist deformation caused by temperature changes and ensure the stability of the material.

2. Excellent thermal shock resistance: It can withstand sudden changes in temperature from cold to hot, reducing the risk of material cracking.

3. High high - temperature load - bearing strength: It can still maintain high mechanical strength at high temperatures, ensuring the safe operation of equipment.

4. Outstanding spalling resistance and corrosion resistance: It can effectively extend the service life of equipment and reduce maintenance costs.

5. Extremely low glass - phase content: It improves the purity and stability of the material and reduces the impact of impurities on performance.

6. Good fluidity: It is convenient for processing and molding, improving production efficiency.

7. Free from metal impurities: It ensures the purity of the material and avoids contamination of products.

Fused mullite has extraordinary performance and is currently widely used in the refractory material fields of industries such as special ceramics, glass, and steel. It also has broad application prospects in investment casting, kiln furniture, ceramic die - casting pipes, etc. Whether it is the refractory bricks of high - temperature furnaces or the lining materials of smelting equipment, fused mullite can exert its unique advantages and provide strong support for customers' production.